- Howie Fenton

- |

- October 21, 2019

Customers always want work faster but could the ability to turn work around faster become the most important service an in-plant can offer? In our two previous trends articles we discussed how in-plants can prepare for 2020 by overcoming staffing issues and increasing the in-plant's value. In this article we will expand on the importance of fast turnaround time and discuss how it can also shield the in-plant from outside threats.

Cycle time or turnaround time is based on your production workflow. How well you overcome workflow issues determines how fast you can turn around work. Workflow issues plague both commercial and in-plant service providers but the most recent research found it is impacting them differently. The KPI | InfoTrends North American Production Software Investment Outlook Study (2019) asked both commercial and in-plant service providers about their production bottlenecks. While both commercial and in-plants listed "Dealing with the high number of small jobs" as their number one workflow issue, the responses changed after that.

Specifically, in-plants listed "Increasing throughput, shortening production times" as second most important. Why would turnaround time be more important for in-plants? One reason is because that is how their performance is evaluated. In-plants working in healthcare, financial, banking and government are often evaluated based on how well they meet their agreed upon turnaround time also known as service level agreements (SLAs). In contrast commercial printers are evaluated based on sales volume or profitability.

Other research supports the importance of turnaround time for in-plants. In the "Software and Automation Trends in the In-Plant Industry" research (2019) conducted by NAPCO found that "faster turnaround" was the answer to questions: the anticipated results of Web to print software (69%) and the top benefits of implementing Web to print (29%). The research showed that Web to print was one of the critical tools required to reduce turnaround times.

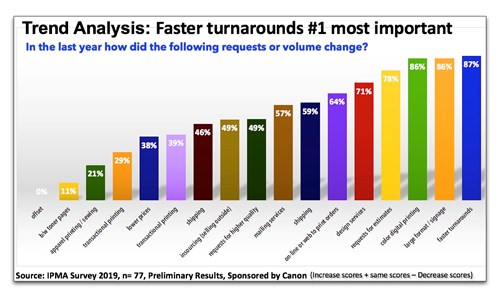

But perhaps the most interesting statistic came from the preliminary results from the IPMA 2019 study. In the research entitled, "The Next Generation Tactics and Strategies for In-Plant Service Providers" when participants were asked if demand for products or services were increasing, decreasing or steady a trend analysis found that faster turnaround time was most important.

How Can Cycle Time Increases Value and Protects In-plants

As we discussed in the RSA Whitepaper "How Web to Print Ordering Impacts Customers’ Satisfaction and the Customer Experience" consumers are comparing all their purchasing experiences to Amazon. Called the Amazon Effect, this includes online ordering, progress emails, offering multiple shipping options, and one or two-day turnaround service. Companies that can provide more of these services are receiving higher customer experience grades.

In addition, providing one day or overnight service may be one of the most powerful weapons to battle against threats from outsourcers and facilities management (FMs) companies. One of the main weapons used by outsourcers or FMs companies is price. They compare their price/product to your price/product and predict a savings over a year. Typically, their savings are about 30% and range from $1-$3M depending on the size of the in-plant.

The catch is that the outsourcers or FMs are bidding work based on their typical turnaround times which are 2-3 days. In-plants that provide 24 hour or overnight turnaround time have a significant advantage because the outsourcers or FM's typically charge a service fee of 25%-50% per product for faster turnaround times. In-plants that prove they produce a portion of their work (10%-30%) within 24 hours or overnight will never get beat on cost.

Summary

Reducing turnaround time provides benefits for in-plants. It can enhance the customer experience and help protect the in-plant from threats from outsourcers or FM's. This shield helps defend the in-plant from a cost attack when the outsourcers or FM's are basing their prices on normal turnaround times. To accomplish this, we have seen some in-plants stagger their shifts with production people coming in at 5AM-6AM and print out the "easier" work, or work requiring less finishing to go out for delivery by 9AM and 11AM. In-plants that can consistently provide a portion of work as overnight or one day service are less likely to be threatened by external providers because of price.