- Howie Fenton

- |

- February 16, 2018

This is the first in a two-article series about understanding and improving costs.

In any business, some mistakes are costlier than others. In our opinion, some of the most dangerous mistakes for in-plant print centers are the ones that get back to the administration or executives, such as price complaints. Few subjects create as much anger as when customers feel "ripped off."

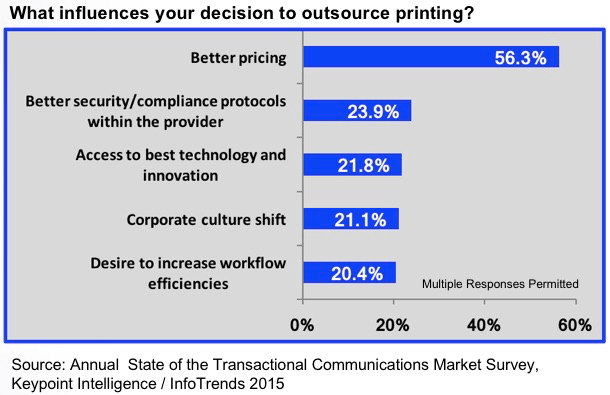

In today's competitive environment with Web to print ordering and Amazon delivery driving costs down, everyone demands lower costs. As a result, unanswered price complaints are dangerous for two reasons. First, they can go up the corporate ladder and fall on the desk of someone that believes in outsourcing, and second, it will provide a talking to point for them. Remember that better pricing is the number one reason companies consider outsourcing.

Outdated Time Standards x Budgeted Hourly Rate (BHR) = Incorrect Pricing

As most people know, the standard operating procedure for job costing in the printing industry is the BHR (budgeted hourly rate) analysis. It is simple in theory: add together each of the cost centers' BHR x time + materials to estimate the cost. In reality, it is time consuming to calculate, often requiring weeks to update. As a result, it is not updated every year, as recommended. Instead of taking the time to update costs correctly, companies make "adjustments." The price of paper goes up and an adjustment is made. The price of consumables goes up and an adjustment is made. The cost of utilities, insurance, or something else goes up and adjustments are made.

But there is an underlying assumption when making these adjustments that only the budgeted hourly rates (BHRs) will change, while time to perform each task (time standards) will remain the same. In other words, the time to estimate a job, schedule and plan a job, preflight a job, correct a file, and proof a file will remain the same. Unfortunately, this is a dangerous assumption because, this often is incorrect. When production print in-plants add new products, such as variable data printing or cross media marketing, time estimates for estimating, customer service, and other cost centers are much longer.

Why is this important?

Not knowing a key element of your true costs- time- can hurt you. If your costs are too low, then you may not be able to meet your financial objective of breaking even or making money. If your costs are too high, you are opening the door to companies who want to close your doors (FM or outsourcing). If you are unsure if your pricing is correct, perform some spot tests (a small or limited number of sample checks done randomly). It only takes two days to spot test for pricing issues. Don't have time to work on spot checks? Contact us to do it!

Our next article will address how to benchmark your administrative time.