- Howie Fenton

- |

- June 17, 2017

This in-plant primer article is the sixth in a 12-article series designed to help dealers and print vendors understand in-plants called "In-Plant Primer: From Operations Basics to Advanced Sales Concepts." All topics were announced in our first post. This last article in the 101 Primer (Trends and Challenges) will focus on what to ask to identify where opportunities may be to offer a production workflow solution to solve common in-plant challenges and issues.

Key Take Aways

- Asking good questions is one way to demonstrate to an in-plant prospect that you've done your homework and want to learn more about their business.

- One of the differences between leading and average sales people is their ability to customize follow-up questions based on answers to previous questions.

- It's always best to ask open ended questions. Specifically, questions beginning with what or how are effective while questions beginning with why may put the prospective customer on the defensive.

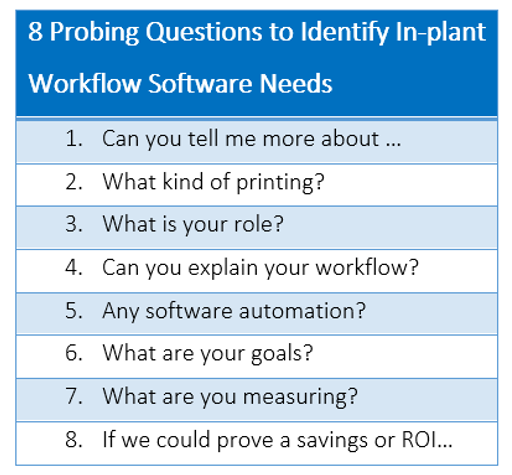

8 Questions to Identify In-Plant Workflow Solution Opportunities

There was a time when a salesperson could sell anything simply by getting excited and enthusiastic about the product. Today, learning through listening and asking probing question has become more important. Good open-ended questions can help you: learn more about the customer, prove that you're interested in their process, and when done right can shepherd a prospect down a path that results in them feeling that they need to buy your solution because it makes the most sense. One of the goals of early sales calls is to ask the right questions at a high level and then take the conversation down a path that helps identify the business issues and challenges and strategies to address those issues and challenges. Here is a template of eight questions to help drive that conversation:

- Can you tell me more about the company? How old is it, how many people work here, is the business growing or shrinking?

- What kind of printing is done here? Is it offset, digital, or both? What are the most commonly printed products? Is it stationery products, bills and statements, marketing materials, books, educational material, etc.?

- What is your role? Are you the production manager, C level executive, customer service representative, prepress manager, mail room supervisor? What are your concerns or pain points in the process?

- Can you explain to me the production workflow? How does a job ticket start? Who are the people in the process? What does each person do? Is there anywhere in this process where the work piles up because of a bottleneck?

- Is there any software automation already in place? Do you have estimating software, e-commerce or Web to print software? Print MIS or prepress PDF-based workflow software?

- What are your goals? What do you want to accomplish? Are you trying to increase productivity, overcome quality issues, overcome pain points for work, or meet deadlines better?

- Are you using measurements and operations to quantify productivity?

- How do you justify investments that help increase productivity?

- If the answer is yes, what are you measuring? How would a change, such as buying software increase productivity?

- If we could show you how software automation increases productivity, reduces labor time and cost, and lowers the time and cost to manufacture, would you be interested in learning more about that?

Follow up the Questions with Expert Workflow Resources like RSA's Team

The most successful sales people today have an in-depth knowledge of customers goals, the production workflow, and the main issues (cost, turnaround time, etc.). When used properly, asking probing questions is a strategy that can walk prospects down a logical path that may result in them concluding that they need a solution that does what you are offering them. Follow up your questions by bringing in an expert resource like the team at Rochester Software Associates (RSA) to help identify areas where workflow solutions like RSA's can easily improve an in-plant's operation This was our final 101 primer article. Watch the for the eBook compilation soon. Next month, we'll start our second primer, "In-Plant Primer 201: Operational and Financial Concerns." The 201 primer will cover more advanced topics such as:

- The different in-plant financial models and how those impact purchases

- Terms and language to use and avoid with in-plants

- How in-plant managers and administration may look differently at the in-plant

- The importance and challenges of measuring operational performance for in-plant managers and their management

- How software automation increases the value of an in-plant.

Access Your Partner Portal to Listen to Our Webinar: From Operations Basics to Advanced Sales Concepts

Access your RSA partner portal now to listen to our webinar about all 12 topics in the Operations Basics to Advanced Sales Concepts primer series.

Both in-plant primers in the series are also available in your partner portal.