- Elisha Kasinskas

- |

- October 25, 2018

Businesses of all shapes and sizes rely on production printing as part of their customer communications, marketing and billing functions. But as vital as it may be, production print can also be slow, costly and complicated. Where processes are manual, they are prone to errors that can add more time and cost to print jobs. At the same time, it can be difficult for users to submit, get estimates, track, and pay for jobs, which can create customer service problems. To avoid these headaches, many businesses opt to outsource production printing, even if it means relinquishing a bit of control over some important business processes at the same time. But thanks to these three production print workflow hacks, businesses can optimize their transactional and graphics arts production printing processes while reducing costs without adding staff.

1. Simplify Job Submission, Tracking and Billing Processes

You'd think that submitting, tracking and paying for production print jobs would be as simple— but it isn't. While print management and workflow solutions aimed at the office have made it simple and easy for office workers to submit print jobs on-demand on a local MFP, it can be a whole different ball game in the production print landscape.

In the production print environment, this is problematic for a few reasons. For one, anything but a smooth and simple job submission will drive most customers into the arms of the competition. And without concrete job tracking and job management tools, customers and production print staff will have a hard time knowing where a particular job is in the production process or managing jobs against due dates without some sort of job management system in place. At the same time, slow billing processes mean customers that are internal to the print shop’s organization (in-plants) don't know where they stand against their printing budget or the printing entity has to wait to receive the revenue.

But with a Web to print solution, dealers can help customer replace inefficient, clunky job submission (like email) and billing processes with job submission functionality that isn’t much different from ordering a pizza. Instead of confining job submission and quoting to business hours, Web to print solutions enable on-demand job submission, instant estimates and even preview how a finished job will look. Customers can save job settings (called ticketing) and user profiles (like billing and shipping information) for frequently recurring jobs, and easily order and re-order them. Additionally, some Web to print systems like RSA's in-plant Web to print, can automate the chargeback process for printing costs to internal/in-house customers so they never go over their budget, or offer other options like credit card and payment options, so print providers can realize revenue faster. Web to print can also help businesses accurately track job status and touches, and report on or provide notifications to customers and print center staff about these items.

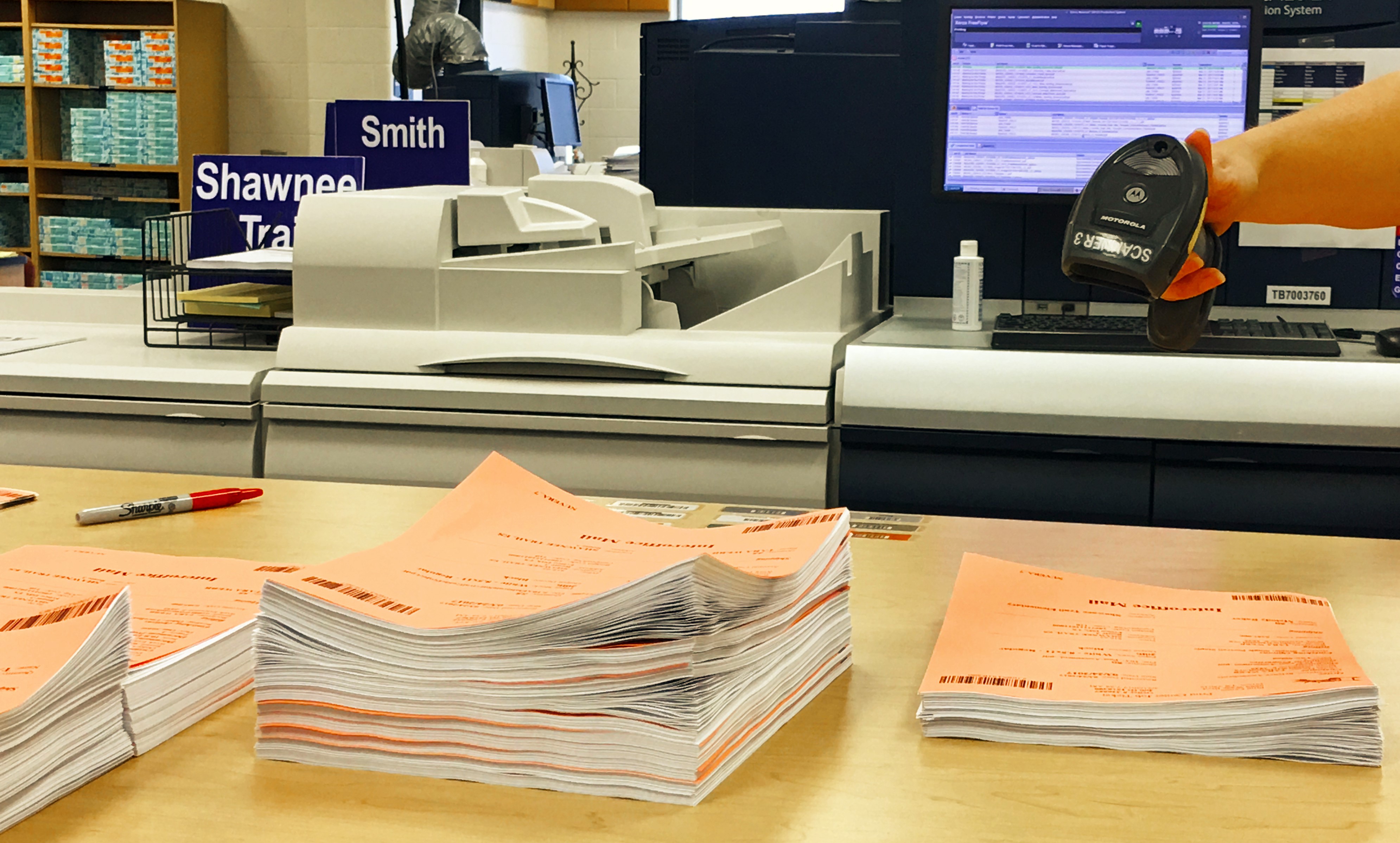

2. Automate Everything: Reduce Touch Points

Traditionally, production print workflows were highly manual and full of "touches" — instances where human intervention is required. As jobs are submitted, production print professionals must make decisions in real time about which device should be used for each job. If they choose the wrong device, operators can create delays and bottlenecks and add additional costs to jobs. Even after professionals have decided which device to use for each job, they need to navigate a complicated setup process, which can contribute to higher costs because of waste, while slowing down how fast they can turn around the job. And if any job ticketing or special instructions are missing, job production can grind to a halt, or worse, be produced incorrectly.

But with production print workflow solutions, dealers can help businesses automate almost every part of the printing process that a computer can handle. Instead of relying on print shop professionals to manage job prioritization and load balancing, production print workflow solutions like RSA's QDirect output manager can automatically determine and route jobs to the device that is best for the job. Automation solutions can even eliminate the need for print shop staff to input job settings. Ultimately, dealers can leverage software to relegate these slow and mistake-laden processes to computers, so in-plant and production print professionals can spend more time on processes that require a human's touch.

3. Eliminate Outsourcing, Cut Costs, and Give them Complete Control Over Print Processes

Because of cost considerations and technological limitations, some businesses opt to outsource their production printing needs. But advances in digital production printing technology and workflow automation solutions have made it possible — and in fact, more efficient and cost-effective — for businesses to bring their transactional and graphics arts production print process in-house.

In the case of graphic arts printing, in-house printing gives marketers more control when it comes to bringing their vision to life. Since printing is handled in-house, the marketing department can rush jobs to meet deadlines and spend more time perfecting their vision. All while holding down costs by producing print in-house.

Ultimately, dealers can leverage these production print hacks to help customers do more with less. Workflow automation solutions can shrink production printing processes, reduce costs, and enable their staff to focus on customer-facing or revenue generating tasks. Meanwhile, Web to print solutions provide customers with a simple and easy way to submit and pay for print jobs and output management software automates job management functions so production printer centers can provide better customer service and reduce costs.

Learn More About How You Can Help Your Customers Take Advantage of These Three Hacks.

Make your customers' production print workflow more efficient. Contact your RSA Business Development Manager to learn how. The money you help your customers save might just be spent with you on a new device!